Web Sling Service

Hercules SLR Web Sling Service: Inspection, Test, Maintenance, And Certification

According to Canadian law, web slings must pass an annual safety inspection by a qualified professional.

Hercules SLR provides ASME standard inspection, testing, and certification services for all web slings.

The consequences of incorrect maintenance and inspections can be life or death. Not to mention the immense financial impact an accident can have on a business.

Bring your web slings to one of our shops across the country or have our trained service professionals come to you.

All inspections are carried out in accordance to ASME standard B30.9.

For Inspections, Load Testing and Certifications Contact the web sling service experts at Hercules SLR today.

Web Sling Inspection & Certification

Frequently Asked Questions

How often should web slings be inspected?

– Normal Service—yearly

– Severe Service—monthly to quarterly

– Special Service—as recommended by a qualified person

– Intervals between inspection should never exceed one year. Written records are not required for frequent inspections, however written records should be kept. The WSTDA, RS-1 and ASME B30.9 require written record of the latest inspection.

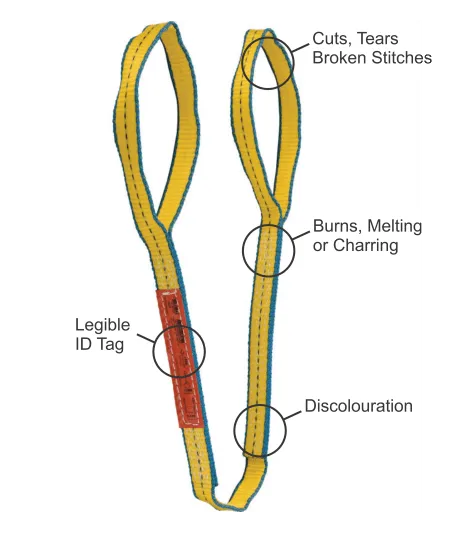

What kind of damage makes a synthetic web sling unusable?

– Increased stiffness of sling material.

– Acid or caustic burns.

– Melted, burned or weld spatter damage.

– Holes, tears, cuts, snags.

– Broken or worn stitching.

– Excessive abrasive wear.

– Knots in any part of the sling.

– Crushed webbing or embedded particles.

– Bleached sling color.

– Defective fittings (twisted, corroded, cracked, etc.)

Exposure to extreme temperatures (lower than -40°C or higher than 90°C)

What are the tag requirements for web slings?

– Must be present and legible

– Name or trademark of a manufacturer

– Manufacturer code or stock number

– Rated loads for the type of hitches used and the angle upon which it is based

– Type of Synthetic web material

– Number of legs if more than one

– Serial number or batch number

– A sling can be rejected due to a combination of problems

Where can web slings be serviced?

– Customers can come to one of our shops across the country or we can come to you with our Mobile Testing Unit. Technicians at Hercules SLR are trained and certified with LEEA accreditation. All inspections are completed within ASME standards.

Why is it important to get web slings inspected after purchase?

Types of inspection

A. Initial Inspection – Before any new or repaired web sling is placed in service, it shall be inspected by a designated competent person to ensure that the correct web sling is being used, as well as to determine that the web sling meets the ap–plicable requirements.

B. Frequent Inspection – This inspection should be conducted by the person han–dling the sling each time the sling is used.

C. Periodic Inspection – This inspection shall be conducted by the designated staff.Frequency of inspection should be based on frequency of web sling use, severity of service conditions and experience gained on the service life of web slings used in similar applications. Inspections should be conducted at least annually.

Removal Criteria

Remove the sling from service if any of the following is visible:– If sling rated capacity or sling material identification is missing or not legible– Acid or alkaline burns– Melting, charring or weld spatters on any part of the web sling– Holes, tears, cuts, snags or embedded particles– Broken or worn stitching in load bearing splices– Excessive abrasive wear– Knots in any part of the web sling– Excessive pitting, or corrosion, or cracked, or distorted, or broken fittings– Any other visible damage that causes doubt as to the strength of the sling

Inspection Records

Written inspection records, utilizing the identification for each sling as establishedby the user, should be kept on file for all web slings. These records should show adescription of the sling and its condition on each periodic inspection.

Repair of Web Slings

Web slings with structural damage shall never be repaired. Web slings utilizing hardware may be rewebbed. The fittings must be visually inspected and proof tested before they can be used.