Round Sling Service

Hercules SLR Round Sling Service: Inspection, Test, Maintenance, And Certificatio

round sling inspection : According to Canadian law round slings must pass annual safety certification inspections by qualified inspectors.

round sling inspection : According to Canadian law round slings must pass annual safety certification inspections by qualified inspectors.

Hercules SLR provides ASME certified inspection, testing, and certification services for all round slings.

The consequences of incorrect round sling maintenance and inspections can be life or death. Not to mention the immense financial impact an accident can have on a business.

Trust the round sling service experts at Hercules SLR to thoroughly inspect, test, and certify your lifting slings. Bring them to one of our shops across the country or have our trained service professionals come to you.

All inspections are carried out in accordance to ASME standard B30.9.

For Inspections, Load Testing, Repair and Certifications Contact the round sling service experts at Hercules SLR today.

Round Sling Inspection & Certification

Frequently Asked Questions

How often should round slings be inspected?

– Normal Service—yearly

– Severe Service—monthly to quarterly

– Special Service—as recommended by a qualified person

– Intervals between inspection should never exceed one year.

Written records are not required for frequent inspections, however written records should be kept. The WSTDA, RS-1 and ASME B30.9 require written record of the latest inspection.

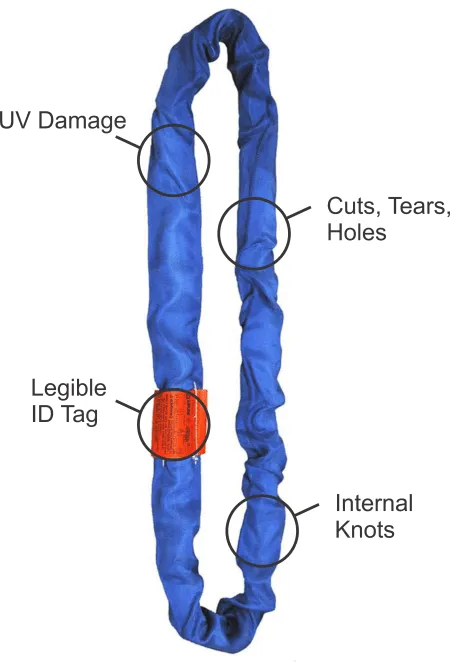

Common signs of wear when inspecting a round sling?

– Missing Identification tag.

– Holes, cuts, tears, snags that expose core yarn, excessive abrasive wear.

– Broken or damaged yarn core.

– One or more knots are tied to a round sling.

– Acid or caustic burns on the round sling.

– Melting, charring or weld spatter of any part of the round sling.

– Distortion, excessive pitting, corrosion, or other damages to fitting(s).

– Broken or worn stitching in the cover which exposes the core yarn.

– Any conditions that cause you to doubt the round slings’ strength.

Synthetic Round Sling Inspections

Synthetic round slings are an integral part of heavy-lifting and rigging. Similarly, proper sling inspection is integral to ensure the job is done safely and properly.

Initial Inspection Before First Use

– Check that WLL and other characteristics of the sling correspond with the lifting application.– Check that manufacturers certificate is available, showing correct traceability between sling and certificate (Material number and batch/ id. number of the sling, shall be covered by the certificate).

Inspection Before Each Use

Inspect the sling for visible defects and ensure that all labels and markings are in good condition. If any doubts exist, remove the sling from service, for examination by a competent person.

Signs of defects or damage can be:

– Damage at cover (loadbearing core yarn visible).– Damage at seam.– Flaking of the surface which may be rubbed off. (Chemical attack)– Glazed or melted surface (heat or friction damage)– Deformed or otherwise damaged fittings

Periodic Inspection

Periodic inspection: Periods for inspection should be determined by both the working environment and frequency of sling use. Slings shall be examined by a competent person, at least once a year, or subject to the local statutory regulations. Records from examinationshall be maintained, with full identity of the sling. If any doubts exist, the sling must beremoved from service and examined by a competent person.

Repair round sling

Repairs to slings can only be by carried out specialists. Never try to repair a sling by yourself.Call our experts at Hercules SLR for all your sling inspection.

Storage

After use, slings must be inspected. Damaged slings shall be repaired or replaced, and undamaged slings must be stored in a dry place, protected from harmful environments. (e.g. chemicals and strong UV radiation) 3 Wet slings must be carefully dried, before storage.