Product Spotlight | What are Plate Clamps?

Product Spotlight | What are Plate Clamps?

What do you do when you need to lift a beam, pipe or piece of sheet metal with no lifting point? AND you’re told you’re not able to cause any surface damage to the material? Easy—You grab a Plate clamp!

Plate clamps are used to latch onto plates, sheets, grinders, pipes and other materials for positioning, hoisting and transferring. This eliminates the need for creating a hitch or drilling into the material. When in use, plate clamps use powerful springs that allow the clamp to essentially become one with the material being lifted (yes, it holds on THAT tight). Most often, plate clamps are used on sheet, plates or fabrications— Because of this, many people know plate clamps as ‘lifting clamps’ or ‘sheet clamps’.

What are Plate Clamps? | Types of Plate Clamps

There are many different types of plate clamps, but the majority of

them fit within two categories—Vertical plate clamps and horizontal

plate clamps. The following are some examples of plate clamps sold by

Crosby!

clamps sold by

Crosby!

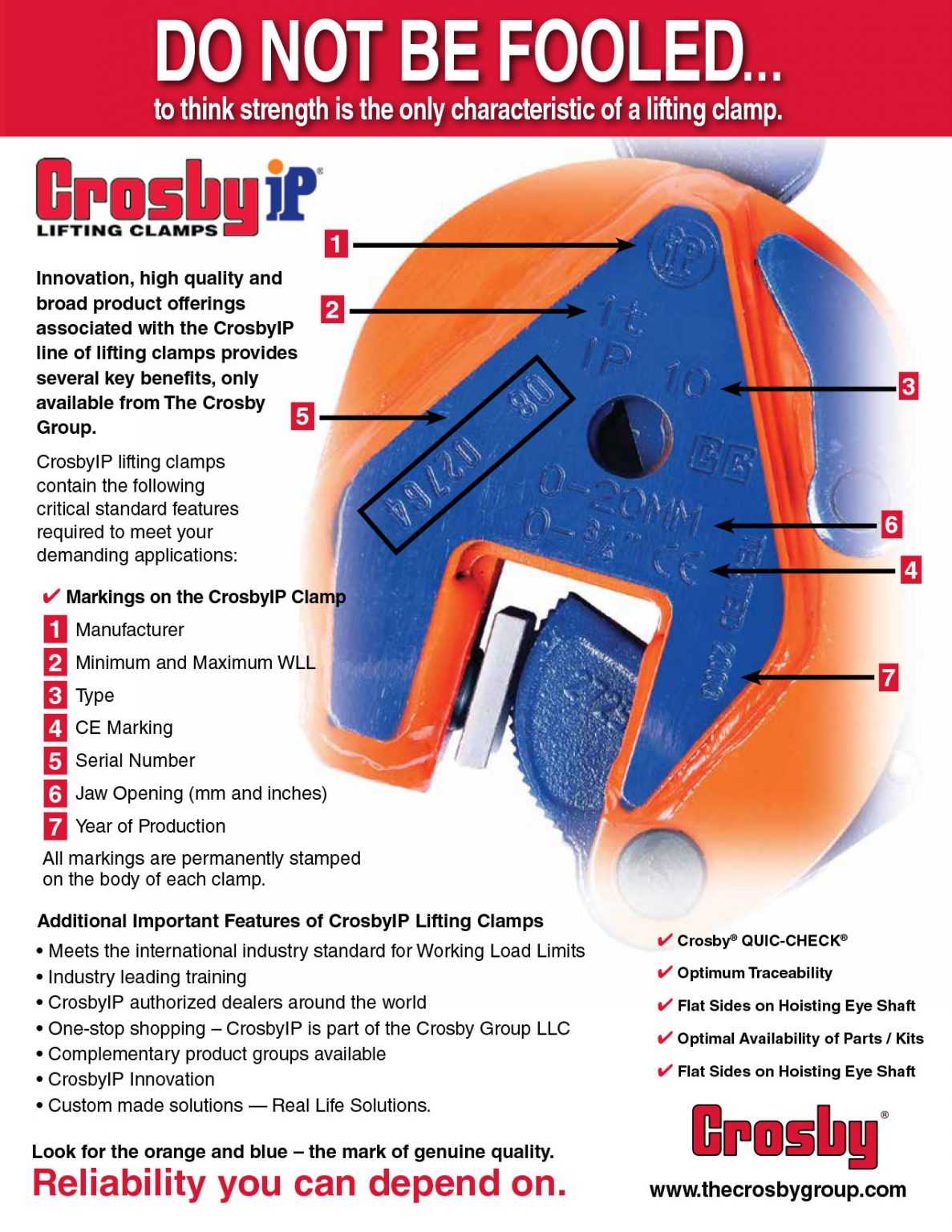

Hercules SLR sells Crosby plate clamps with a variety of working load capacities and jaw opening sizes. Crosby plate clamps are produced using advanced manufacturing techniques and are able to withstand abusive field conditions. Each plate clamp, beam plate clamp, and drum clamp features a welded alloy steel body that is designed to have high-strength while still being lightweight and compact. Crosby plate clamps are individually proof tested to two times the working load limit and you’ll always find the Crosby logo, working load limit (WLL), jaw opening, unique serial number, and proof load test date permanently stamped on the clamp bodies.

Did you know you can now shop online at Hercules for your Plate Clamps? More Products being added regularly!

Vertical Plate Clamps

Vertical plate clamps are used for lifting, turning, moving or vertical transfer of sheet plates, or fabrications from horizontal to vertical and down to horizontal (180 degrees) as need.

- The IPU10 has a hinged hoisting eye which allows for the clamp to place and lift the load from any direction, or with a multiple leg sling without side-loading the clamp. The IPU10S is for use with stainless steel and the IPU10H is for use with materials with a surface hardness up to 47Rc (450 HB)

- Available in capacities of 0.5 through 30 metric tons (higher WLL are available upon request).

- Wide variety of jaw openings available from 0″ to 6.1″.

- The IPNM10N will not mark or scratch the material

surface, making it suitable for materials such as aluminum, stainless

steel, painted materials, aircraft skins, composite material, glass, and

plastic. The IPNM10P does this while also providing a protective cover that will reduce the risk of damage to surrounding plates.

- Available in capacities of 0.5, 1 and 2 metric tons.

- Wide variety of jaw openings available from 0″ to 1.57″.

- The IPU10A automatically clicks on to the material

as soon as the clamp is placed on the plate. The safety lock will remain

in position as the clamp closes precluding hazardous situations. This

also allows the clamp to be easily fastened to difficult to reach areas.

- Available in capacities of 1 and 2 metric tons.

- Wide variety of jaw openings available from 0″ to 1.97″.

Horizontal Plate Clamps

Horizontal plate clamps have a pretension feature that allows users to attach the clamps to the material for horizontal lifting and transfer of non-sagging material. These clamps must be used in pairs or more.

- The IPHNM10 may only be used on material surfaces that have no damage and the IPH10 and IPH10E have spring-loaded tension.

- IPHNM10 and IPH10 are available in capacities of 0.5 through 12 metric tons and IPH10E are 2.0 through 25 metric tons.

- Jaw openings available from 0″ to 4.75″ (IPH10E only goes to 4.72″)

- The IPHOZ is used on thin sheets and other materials that will sag or bend when lifted.

- Available in capacities of 0.75 through 15 metric tons.

- Wide variety of jaw openings available from 0″ to 2.36″.

- The IPBC has clamps with a pretension feature that

allows the user to attach the clamps to sagging and non-sagging

materials. These clamps may also be used to handle material that will be

used in shears, bending and rolling machines or other fabrication

equipment. This clamp may also be used for turning beams from the “H”

into the “I” position. IPHGZ and IPHGUZ have these capabilities and may also be used to move and life structural shapes such as I-Beams, H-Beams, etc.

- Available in capacities of 1 through 4.5 metric tons.

- Jaw openings available from 0″ to 1.57″.

- The IPPE10B(E) is suitable for use on bundles or

unbendable sheets of metal. The jaw opening can be easily adjusted for

the height of the bundle or the plate. It also has magnets in the

footplate, allowing one person to operate multiple clamps at the same

time when lifting loads. IPPE10BNM may be used for

virtually all applications, where the objects that are being lifted or

transported require optimal protection against surface damage.

- Available in capacities of 3 and 12 metric tons.

- Wide variety of jaw openings available from 0″ to 7.09″.

Specialized Clamps

Crosby also makes plate clamps for further specialized uses such as beam plate clamps, shipbuilding clamps, positioning screw clamps, pipe grabs, beam clamps, concrete road barrier grabs, granite curb grabs, and pipe hooks. If you’re interested in learning more in-depth information about these specialized clamps, email us or call us at 1-877-461-4876.

What are Plate Clamps? Their Uses

- The Mining/Quarrying Industry – Many extracting and maneuvering operations use plate clamps capable of meeting the needs of extreme conditions found in everyday operations within the mining/quarrying industry.

- Transportation/Towing Industry – plate clamps are used in the transportation & towing industry to load vehicles onto trailers, load finished products into containers, and transfer bulky items used in production and construction.

- Construction Industry – plate clamps are on many materials within the construction industry such as fabricated building materials like iron sheets, heavy doors, windows, metals pipes, timber, floors or walls.

- Steel Industry – You’ll likely find plate clamps in most foundries and metalworking facilities as plate clamps are used so much in this industry – The hardware is often known as a ‘plate clamp’ or ‘sheet clamp’ (as we’ve mentioned above), because of its use moving plates of steel.

Plate Clamp Dos and Don’ts

Based on safety guidelines recommended by the Canadian Centre for Occupational Health and Safety (CCOHS), here are some easy dos and don’t to keep you and your load safe when using a plate clamp.

DO

- Select the correct clamp for the job – ensure you’re using the correct clamp for directional lifting (vertical, horizontal or universal) and that the clamp is rated for the thickness and weight of the materials being lifted.

- Refer to the manufacturers’ operating instructions.

- Inspect clamps visually before each use.

- Lift one piece of material at a time unless using clamps and methods approved for otherwise.

- Use two or more clamps to balance a long or flexible load (always use two or more if manufacture guidelines suggest).

- Install the clamp(s) over the center of gravity of the load.

- When using vertical plate clamps, consider using a locking device to prevent accidental loosening.

- Always use clamps within their rated capacity and flange width.

- Ensure clamps are locked in place before lifting a load.

- Use slings between the clamp and cranes or hoist hooks.

- Use non-marring (rubber pad) clamps in pairs when lifting finished and polished plates

- Lift smoothly and avoid jolts.

- If the use of a tag line is necessary, attach it to the clamp before lifting the plate.

DON’T

- Do not lift over workers and do not stand near a load – Position yourself away from the load. Remember to also consider how the load might fall when it lands.

- No not overload or underload a clamp.

- Do not lift from the side with a vertical-only clamp.

- Do not attempt to lift materials from the bottom of a stack.

- Do not drag the load using the plate clamp.

- Do not use a clamp having a minimum jaw opening larger than the thickness of the load.

- Do not leave suspended loads unattended.

Plate Clamp Inspections

Before using ANY rigging hardware, you should always perform visual inspections to ensure you aren’t using hardware that’s damaged or weakened, making it unsafe to use.

But, keep in mind these quick visual inspections should not and DO NOT replace any required annual inspections. Without inspections and maintenance, equipment failures can have a major effect on safety, unscheduled outages and your business costs. Hercules SLR has qualified technicians to inspect and repair your securing, lifting and rigging equipment on-site or in one of our full service, rigging shops. Our experienced and LEEA certified team will ensure that your equipment complies with ASME and provincial regulations. Staying on top of your required annual inspections has never been easier with the Hercules SLR team.

How to visually inspect the exterior of a plate clamp

- Always follow the hardware’s manufacturer maintenance recommendations.

- Inspect internal and external surfaces for forging or weld fractures, wear or distortion.

- Check all pin holes for wear.

- Inspect the throat (clamp opening) width – At zero grip, the clamp should be in full contact with the pad.

- Measure the width of the throat – If the measurement at the base (where the pad is located) is greater than at the top, the body has been overloaded and the clamp and tag need to be replaced.

Crosby is one of the most recognizable names in the rigging industry, and has been for over 100 years. Crosby makes over 2,000 rigging and lifting products to meet all your hoisting needs, and Hercules SLR is proud to be an Authorized Crosby Distributor and a Certified Crosby Repair Center.

See your Crosby gear from purchase, all the way to service with Hercules SLR’s extensive product selection, inspection & service team, asset management, testing and more.

——————————————————————————————————————————————

The Hercules Group of Companies encompasses a wide portfolio of products and services across 7 diverse companies.