5 Top Tips | Using Ratchet Straps Correctly & Safely

5 Top Tips | Using Ratchet Straps Correctly & Safely

One of the most popular methods for securing cargo, especially when it comes to shipping, is using ratchet straps – also known as lasing straps or tie-downs. Ratchet straps are the hammer of the transporters toolbox – with applications ranging wide from professional use to everyday common use. You may not realize it, but these simple straps are a large and important component in material handling.

As with any material handling equipment, it is important that you use it correctly, and take proper care of it. Your equipment is what keeps your load, yourself and your employees safe – so it’s your job to make sure it is set up for success! In this blog, we’re going to be sharing our 5 top safety tips to ensure your ratchet straps are being used to their full, and proper, compacity!

1. Using them Properly

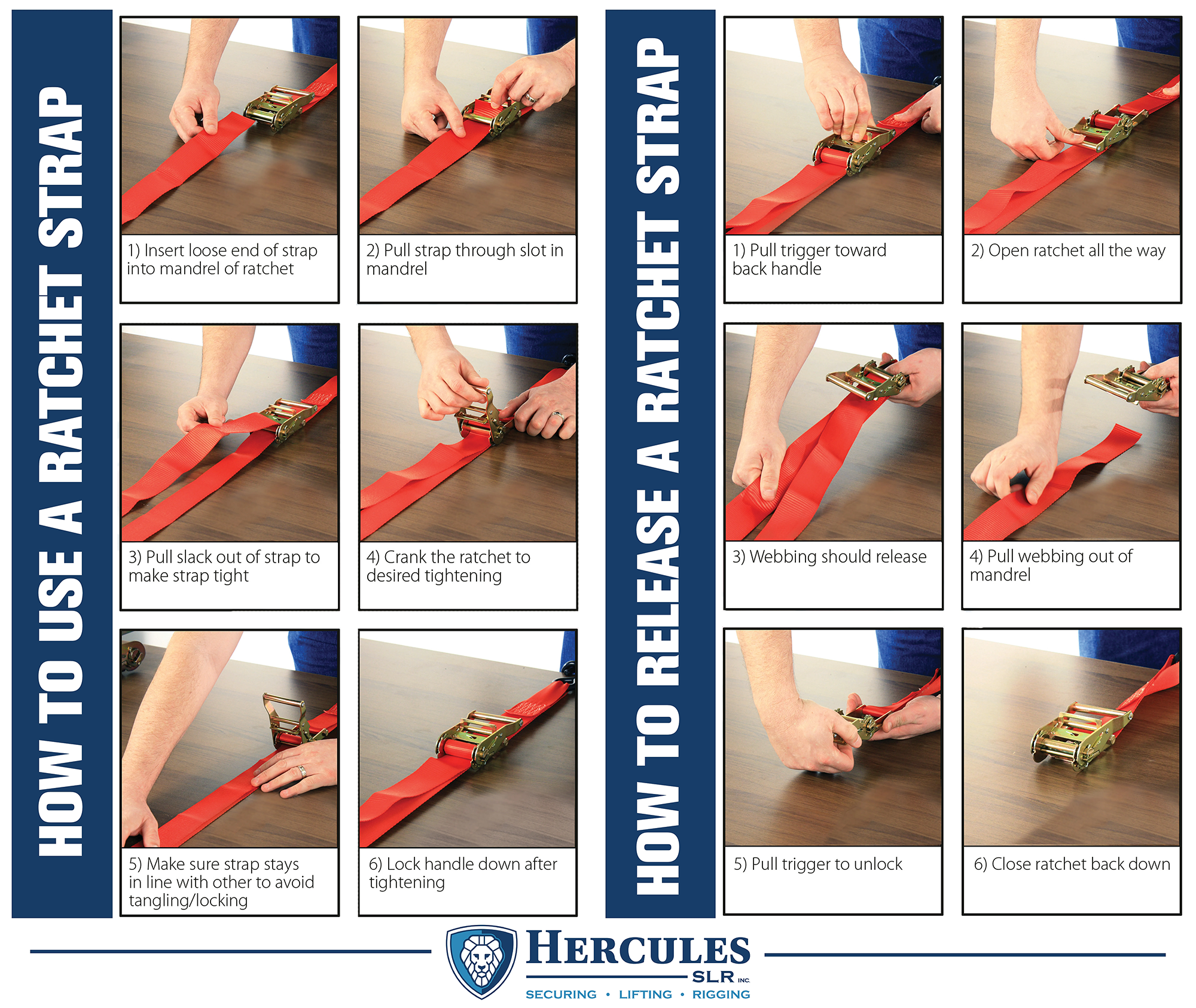

When not used properly, ratchet straps can become damaged very quickly, and potentially cause road hazards. The proper way to use a ratchet strap is:

How to Use a Ratchet Strap

- Step 1: Insert loose end of strap into mandrel of the ratchet

- Step 2: Pull strap through slot in mandrel

- Step 3: Pull slack out of strap to make strap tight

- step 4: Crank the ratchet to desired tightening

- Step 5: Make sure strap stays in line with other to avoid tangling/locking

- Step 6: Lock handle down after tightening

How to Release a Ratchet Strap

- Step 1: Pull trigger toward back handle

- Step 2: Open ratchet all the way

- Step 3: Webbing should release

- Step 4: Pull webbing out of mandrel

- Step 5: Pull trigger to unlock

- Step 6: Close ratchet back down

2. Storage Methods

The working life of your equipment is affected by more than just how you use it – storing it incorrectly is one of the leading causes of damage. There are three main things you want to avoid when storing ratchet straps:

- Moisture – Storing ratchet straps is a place where they are exposed to moisture can cause it to mold and mildew. Mold can extremely weaken the strength of the webbing and the polyester can actually be destroyed, even in heavy-duty straps. This is a problem many people run into when choosing to store their ratchet straps in the back of their truck. This is also something to be aware of when using the straps in the rain – always ensure they are able to dry before putting them away.

- Direct Sunlight – Ratchet straps should always be stored in a dark, dry place away from direct sunlight. When exposed to harmful UV rays, they can get sun damaged – you’ll notice this by seeing the color of the strap fade.

- Friction & Heat – Exposer to heat, such as the sun, fire, or other heat sources can cause weakening issues. This can also occur if the straps rub against a sharp edge or other objects while in use. If you notice any burn marks in your straps, they must immediately be placed out of service.

3. Choosing the Right Ratchet Strap

You’ll need to consider the following when choosing tie-down straps:

- Weight capacity (WLL – working load limit)

- Length of straps

- Type of hook: S-hooks, double J-hooks, flat hooks, and E-track systems

- Whether you need extra security offered by tie-down straps that latch or lock

- Whether you want extra protection for your cargo, vehicle, and straps

Weight Capacity of Ratchet Straps

One of the most important things to consider when choosing ratchet straps is their weight capacity. To get the right ratchet straps, you need to know the weight of your cargo and the total number of straps you will use to tie it down.

The weight capacity of a ratchet strap is designated by its safe working load limit (WLL), which is a measure of the maximum weight the strap can safely handle. To safely secure a load, the combined WLL of the ratchet straps used must be greater than the weight of the secured cargo. For example, if your cargo weighs 1,000 lbs and you are using 2 ratchet straps to tie it down, each strap must have a WLL of 500 lbs or greater. It is recommended that you always use ratchet straps in pairs.

Ratchet straps are also rated by their maximum load (or break strength), which is the amount of weight that will cause the ratchet strap to fail. The break strength is usually 3 times the WLL. You should always use the WLL to determine what ratchet straps are best for your application.

Length of Ratchet Strap

Ratchet straps need to be long enough to reach from tie-down point to tie-down point or from your cargo to a tie-down point on your trailer or truck. If the ratchet straps are too short, they won’t work at all. If they are a lot longer than you need, you will have long, loose ends that could get in your way. Even if you are using ratchet straps of the ideal length, there will still be a portion of the strap that must be secured so that it doesn’t flap in the wind. And because the same ratchet straps are often used for multiple applications, it’s almost impossible not to have long ends of the strap to deal with at some time.

4. Using the Right Amount

As we mentioned above, the industry standard is to use ratchet straps in pairs. Depending on the type of cargo you are transporting, there may be specific regulations as to how many ratchet straps need to be used. For example, if you’re transporting goods in pallets, boxes or stillages, you will need at least one strap per row. Or, if you’re transporting logs in a truck fitted with a headboard, you need to use at least one strap per bay for logs up to a maximum length of 3.3 meters with the bark still present. It’s important you look into regulations specifically for your region, industry, and type of cargo!

5. Daily Inspections Checking for Damage

Ratchet straps must be regularly inspected to ensure they are not damaged. Even “minor” damage can drastically reduce the strap’s capacity and increase the chance of failure during use.

The entire ratchet strap assembly must be inspected before each use and removed from service if any of the following are detected:

- If the identification tag is missing or illegible

- Holes, tears, cuts, snags or embedded materials

- Broken or worn stitches in the load-bearing splices

- Knots in any part of the webbing

- Acid or alkali burns

- Melting, charring or weld splatters on any part of the webbing

- Excessive abrasive wear or crushed webbing

- Signs of ultraviolet (UV) light degradation

- Distortion, excessive pitting, corrosion or other damage to buckles or end fittings

- Any conditions which cause doubt as to the strength of the ratchet strap

Hercules SLR can design and manufacture heavy or light duty ratchet assemblies that are weather and wear-resistant and will secure your load properly and safely.

SLR can design and manufacture heavy or light duty ratchet assemblies that are weather and wear-resistant and will secure your load properly and safely.

All our tie-down straps and ratchet assemblies are manufactured from the highest quality proof tested webbing hardware. They can be supplied with any one of several standard or custom made end fittings to ensure that your load is adequately and safely secured. Larger ratchet assemblies are available in standard or long-handled versions.

Hercules SLR is here for you and all your transportation requirements! Load Binders, ratchet straps, tie downs, tarps, chains, ropes, slings, hardware and more. We remain open, while respecting the emergency measures put in place by our provincial governments and health advice.

We have set up specific drop-off and pick-up points in-store and you can call us ahead of time to make sure everything is ready before your arrival. Your safety is our priority and when you need us, we are here for you. Call us: 1 877 461-4876 or visit us online here to find the nearest Hercules SLR branch locations.

——————————————————————————————————————————————

The Hercules Group of Companies encompasses a wide portfolio of products and services across 7 diverse companies.