Types of Load Binders & Choosing the Best for the Job!

Types of Load Binders & Choosing the Best for the Job!

There are two general types of load binders – ratchet binders and lever binders, defined by their method of tightening. Though the majority of commonly used load binders will fall in one of these two categories, they are available in a range of styles, load ratings, and sizes to match the different types of chain used within the transportation industry.

If you’re a part of the transportation industry you’re likely pretty familiar with load binders, also known as chain binders. Load binders are an essential piece of equipment used to anchor loads for transport by applying tension to the chains that tie-down your cargo. Of all tie-down methods, chain and load binders have the most muscle to handle the toughest tie-down jobs – made for big & heavy loads.

A Closer Look at the Different Types of Load Binders

Lever types and ratchet type load binders work similarly and usually are chosen based on the personal preference of the user. As with any type of load securement gear, safe practices need to be followed. Let’s take a closer look at these two categories of load binders with some pros and cons so that you can confidently make the choice of which type of load binder will work best for you.

Lever Type of Load Binders

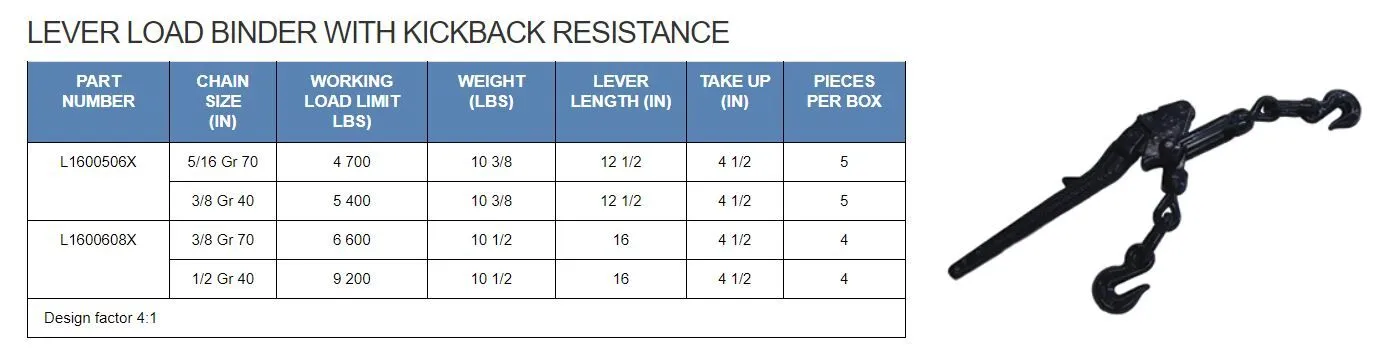

A lever type of load binder (also known as lever chain or snap binders) is made up of a simple machine, a lever, with a tension hook on each end. The lever is used to increase the force applied to a tie-down. The lever is hinged and takes up the slack by pulling on one end of the tension hook and will lock itself after a 180-degree rotation of the lever around the hinge. They require a relatively high manual force to be applied by the person installing the binder in order for it to tighten and secure the chain. While they take more manual force, they are typically quicker and simpler to install because of their straight forward design and application with less moving parts.

Lever Load Binders Pros and Cons

Lever Load Binders Pros and Cons

Pros

- Quicker and simpler to operate

- More compact

- Generally less expensive

Cons

- Requires more manual strength

- The threat of “kickback” from the lever if proper care is not taken

- More likely to break in the handle where kinetic energy is held

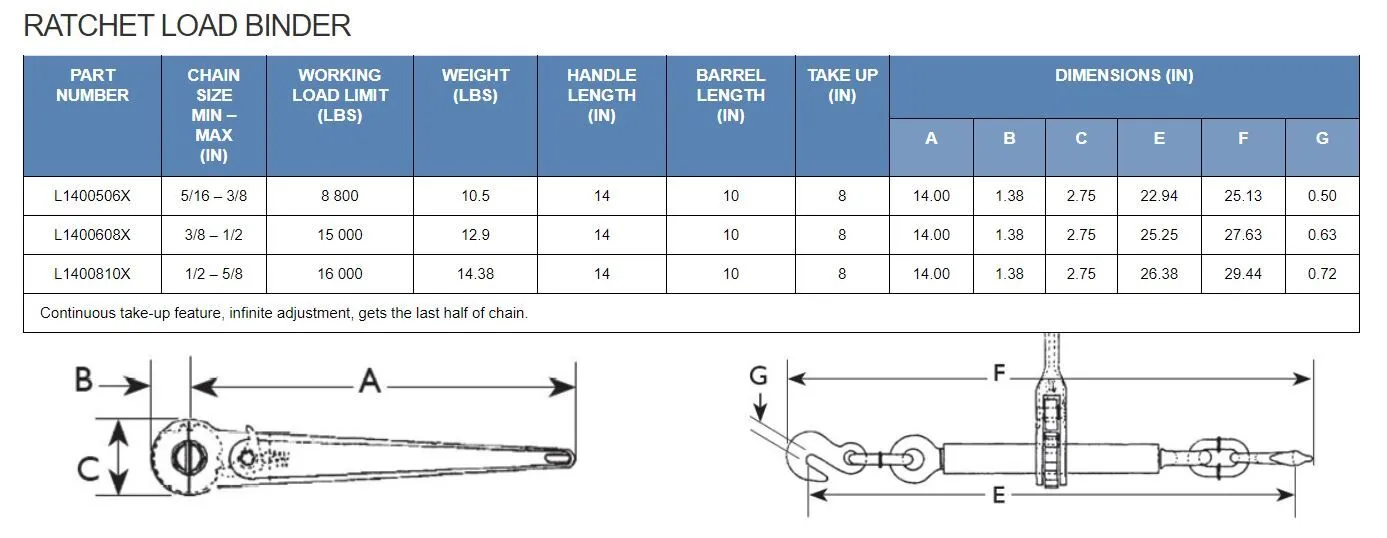

Ratchet Type of Load Binders

A ratchet type of load binder (also known as ratchet chain) uses two types of simple machines and has two tension hooks on each end and handle. The handle again serves as a lever plus there is the screw thread. Having both simple machines can multiply the force manually applied to the tie-down assembly.

When using a ratchet binder, the lever and screw work together and increase the force manually applied to the tie-down assembly. The result is that it takes much less pulling force on the handle to apply tension than you would need with a lever binder. Ratchets also allow for slower, steadier loading and unloading of forces. This reduces any undue stress or strain on your body. Since ratchet binders are designed with a gear, handle, pawl, and end fittings, they will not store up as much energy in the handle as a lever binder will. Another advantage of ratchet binders is that take-up is safer. The take-up distance of a ratchet binder is typically eight to ten inches – twice that of a lever binder. While take-up with a ratchet binder may take a few extra minutes, it is more controlled and ultimately a safer process.

Ratchet Load Binders Pros and Cons

Pros

- Less manual force to operate

- Safer to operate – Not as much energy is stored in the handle, therefore will not “kickback”.

- Higher mechanical advantage

- Easier to adjust in finer increments

Cons

- Generally more expensive

- Less compact

- Harder to operate

- Takes more time to set up

Selecting the Proper Load Binder

Once you’ve made the choice on what type of load binder you prefer, it’s time to ensure you’re using the correct load binder within that category. Making this choice has less to do with the load binder itself and more to do with the type of chain you are using alongside it, and the weight of your cargo. Chains and load binders work together as a team, so you have to make sure they are compatible with each other.

Capacity is the most important considerations when you’re choosing your chain and load binder team. The load being tied down must not exceed the combined WLL (working load limit) of all the chains being used. For example, if your cargo weighs 4,000 lbs and you will use 4 chains, each chain must have a WLL of at least 1,000 lbs. Four chains of 1,000 lbs WLL each will equal 4,000 lbs total, enough capacity to secure a 4,000 lb load. Each binder must also have a WLL of at least 1,000 lbs. A good rule to follow is to always use binders that have an equal or greater capacity than the chains they will tighten.

——————————————————————————————————————————————

The Hercules Group of Companies encompasses a wide portfolio of products and services across 7 diverse companies.