Tips for Forklift Driving Safety

Tips for Forklift Driving Safety | Ask the Experts

Forklift driving takes a lot more than just lifting and moving materials – Forklift operators should have an understanding of safety & balance, to keep materials, themselves, and others safe. One of the biggest risks forklift drivers face is tipping-over. According to OSHA, approximately 25% of forklift fatalities were from tip-over incidents.

Yes, it might seem basic, but it’s important to recognize the forklift’s center of gravity and stability triangle. In this blog, we’ll discuss tips to keep you balanced and everything else you need to know to stay safe in, out, and around the forklift.

In this blog we’ll cover:

- Some of the biggest safety risks associated with balance and the most common type of forklift

- Forklift center of gravity & the stability triangle

- Other factors that contribute to forklift accidents and tip-overs

- How to conduct visual & operational forklift inspections

- Safety tips to remain balanced & safe while driving a forklift

There are four main potential safety risks considering balance and forklift driving. These are:

- How likely the forklift is to tip-over forward;

- How likely the forklift is to tip-over on its side;

- Maximum braking-level (or stopping distance) the forklift can perform;

- The maximum level of reversed-acceleration the forklift can perform.

In Canada, counter-balanced forklifts are one of the most often-seen types of forklift.

FORKLIFT DRIVING | CENTRE OF GRAVITY & STABILITY TRIANGLE

CENTRE OF GRAVITY & STABILITY TRIANGLE

As we mentioned earlier, a counterbalance forklift has three ways it can tip—forward, or sideways, on the left or right.

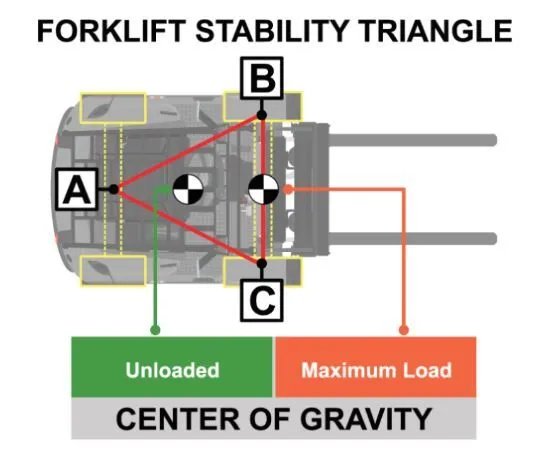

While driving a forklift, it’s important to maintain its center of gravity. The center of gravity lives within the stability triangle.

The Centre of gravity is defined as the point within the triangle where the bulk of the mass is located. Although we don’t recommend trying it out, the center of gravity is also the point where the forklift could balance. Again—Take don’t try this one out, we recommend taking our word for it.

Calculating the forklifts’ center of gravity is complex (and unnecessary for daily use), but there are a few important things to understand in order to remain balanced as you operate the forklift.

When the forklift is stationary, it won’t tip as the force is on the center, but tilts forward when force is applied to the front tines (also called forks) or its back. It’s also worth noting that a forklift is more likely to tip sideways, than forwards. Therefore, adding a load to the front forks decreases the chance the forklift will tip on its side.

Alternatively, lifting the forks on the truck with a load will cause the forklift’s stability to decrease on all sides.

FORKLIFT DRIVING | WHAT ELSE CONTRIBUTES TO ACCIDENTS?

The type of load and how it is placed on the forklift contributes significantly to forklift accidents. First and foremost, you should always avoid awkwardly stacking or piling your load in a way that causes instability. Unmaintained pallets, too heavy of a load, or too tall of a load can also cause a hazard by having the load break apart mid-travel, or by obstructing the driver’s view.

Making sure your forklift is in top shape is also key to avoiding accidents. Another common contributor to forklift accidents is faulty or malfunctioning mechanics. This includes faulty steering, brakes, clutch, transmission or mast assembly, inadequate or malfunctioning safety devices, improper forklift emissions, or poorly organized controls and displays on the forklift.

FORKLIFT DRIVING | SAFETY TIPS

To help maintain the center of gravity, there are three main things to keep in mind with driving a forklift:

- Don’t distribute the load unevenly on the forks, this will increase the frequency of sideways tip-overs

- Don’t load the forklift beyond its WLL, this will make the forklift prone to tipping

- Be sure to move the load all the way to the back of the forks

If you’re driving a forklift, you should never:

- Drive a forklift without any capacity ratings listed

- Travel in a forklift with a load raised more than 4 inches

- Leave the forklift alone while running, or with a load

- Let unauthorized personnel operate a forklift

- Attempt to adjust the load from the operating cab

- Raise a load extending over the load backrest, unless no part of the load can slide back toward the operator

- Use pallets with forks as a make-shift elevated work platform (it’s more common than you think!)

- Let personnel stand/walk under any elevated part of the forklift

It’s important to communicate potential hazards for everyone working in a space where forklifts are found, and use proper signals to keep yourself and others safe. Here are some tips to help keep others safe while driving a forklift:

- Restrict access to areas where forklifts are used (and create procedures to keep workers safe when they must enter spaces where forklifts operate)

- OR, create designated walkways or traveling paths to separate pedestrians from forklifts

- Pedestrians should always let the forklift driver know when they’re in the area—Eye contact is a simple way to make your presence know

- Keep the area, particular the traveling path free from obstacles and ensure it’s well-lit

- Be careful when driving around sharp/blind corners, doorways, and narrow aisles. Honk your forklift horn at intersections.

- Wear hi-vis clothing & PPE

- Load the forks so your line of vision is clear

- Avoid driving the forklift near people-heavy areas

- Don’t walk under or near forks

FORKLIFT DRIVING | INSPECTION

A forklift operator should inspect their forklift daily, at the beginning of each shift and before each use.

The operator should do a visual circle-check of the forklift (a walk-around) and an operational pre-use check. What do these involve?

During a visual inspection before use, the operator should:

- General condition/cleanliness (this includes the forklift and surrounding floor & overhead work areas)

- Ensure a charged fire extinguisher is nearby

- Make sure engine oil, fuel, and radiator fluid levels are correct

- Establish that the propane tank’s fuel-tank mounting system, fuel-tank position pin, propane relief valves, and hose are in good condition

- Make sure the battery is fully charged, there are no exposed wires, plug connections are in good condition, vent caps are clear, electrolyte levels in cells are acceptable and are in-place with hold-downs or brackets

- See that bolts, nuts, guards, chains, or hydraulic hose reels are not damaged, disconnected or missing

- Check for wear, damage, and air-pressure (pneumatic tires) in wheels & tires

- Ensure forks/tines are not bent or chipped and are level & properly positioned—Also check that positioning latches and carriage teeth aren’t broken or worn

- Make sure chain anchor pins aren’t worn, loose or bent

- Make sure there are no fluid leaks, damp spots, or drips

- Ensure hoses are secured and not loose, crimped, or worn

- Check for grease & debris in the operator compartment

- Make sure the seatbelt fastens & works properly

- Guards: Ensure guards, overhead guards, and roll-over protection structure (ROPS) are secure & undamaged

During a pre-operational inspection, the forklift operator should check:

- FOOT & PARKING BRAKE: Ensure pedal holds & unit stops smoothly, and brake holds against slight acceleration

- DEADMAN SEAT BRAKE: Make sure it holds when the operator rises from the seat

- CLUTCH & GEARSHIFT: Make sure they shift smoothly and don’t jump or snag

- DASH CONTROL PANEL: Check that all lights & gauges are operational

- HORN: Make sure the horn sounds loudly enough to be heard overwork

- BACK-UP: Make sure the reverse alarm and other warning devices work properly

- LIGHTS: Ensure headlights and warning lights function properly

- STEERING: Make sure the steering-wheel works smoothly

- LIFT MECHANISM: Make sure they operate smoothly—You can check by lifting forks to their maximum height, then lowering them completely

- TILT MECHANISM: Make sure the tilt mechanism works properly & holds the load—You can check by tilting the mast forward and backward completely.

- CYLINDERS & HOSES: Check these last and make sure they’re not leaking after doing these checks.

BE SURE TO LISTEN FOR UNUSUAL SOUNDS/NOISES!

There are many work-related issues that contribute to forklift driving, safety & general operation.

Ensure you conduct the three types of inspections we cover in this blog, be mindful of the forklift’s stability triangle & forks, keep travel slow, steady & free from obstacles to ensure your safety and others around you—And never let someone drive the forklift without proper training, or who hasn’t been designated.

——————————————————————————————————————————————

The Hercules Group of Companies encompasses a wide portfolio of products and services across 7 diverse companies.