Elevating Excellence: The Crucial Role of Rigging and Wire Rope in Elevators

Elevating Excellence: The Crucial Role of Rigging and Wire Rope in Elevators

Elevators have become an indispensable part of modern life, seamlessly transporting people and goods between floors in buildings of all shapes and sizes.

Behind the smooth ascent and descent lies a sophisticated system of components, and at the heart of this mechanism is the often-overlooked hero – rigging and wire rope. In this blog post, we’ll delve into the historical evolution and technical intricacies of rigging and wire rope in elevators, shedding light on their crucial role in ensuring safe and efficient vertical t ransportation.

ransportation.

Historical Evolution of Elevators

The concept of elevators can be traced back to ancient times, when rudimentary systems were employed for lifting heavy loads. However, it wasn’t until the 19th century that elevators underwent a transformative evolution, thanks to technological advancements and innovative engineering.

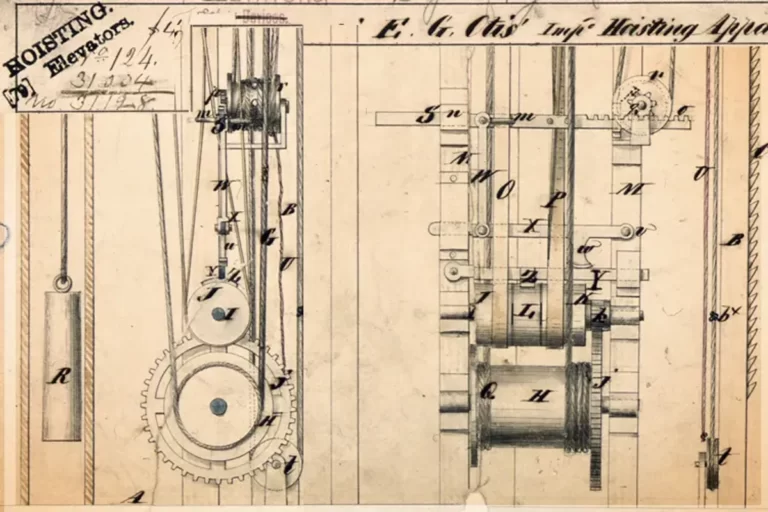

The first commercially successful elevator was developed by Elisha Otis in 1852. Otis’ breakthrough invention featured a safety mechanism that prevented the elevator from falling in the event of a cable failure. This marked a turning point in elevator safety and laid the foundation for the widespread adoption of vertical transportation in buildings.

The Role of Rigging in Elevators

Rigging in elevators refers to the system of pulleys, sheaves, and ropes designed to move the elevator car within the shaft. The primary purpose of rigging is to provide a reliable and controlled means of transportation, ensuring the safety of passengers and cargo. Rigging also plays a critical role in distributing the load evenly, preventing stress concentration on any single component.

Otis Elevator Patent

Wire Rope: The Backbone of Elevator Systems

Wire rope, a key component of elevator rigging, has replaced traditional hemp and steel chains due to its superior strength, flexibility, and durability. The basic structure of wire rope consists of individual steel wires twisted together to form strands, which are then helically wound around a core. This design imparts strength and resilience to the rope, making it well-suited for the demanding conditions of elevator operation.

Technical Aspects of Wire Rope in Elevators

Materials and Construction:

- Modern elevator wire ropes are typically constructed from high-strength steel alloys, ensuring a perfect balance between strength and flexibility.

- The construction of wire rope involves a combination of strands and a core. Strands are composed of individual wires, and the core provides additional support.

Strength and Load Capacity:

- The strength of wire rope is determined by factors such as the diameter of the rope, the number of strands, and the material used.

- Elevator wire ropes are designed to withstand considerable loads, and engineers carefully calculate the appropriate size and configuration based on the specific requirements of the elevator system.

Flexibility and Fatigue Resistance:

- Wire ropes must exhibit flexibility to navigate the sheaves and pulleys within the elevator system.

- To counteract the effects of repeated bending and flexing, wire ropes are manufactured with materials and constructions that enhance fatigue resistance, ensuring a long service life.

Corrosion Protection:

- Elevators are exposed to a variety of environmental conditions, including moisture and humidity. Therefore, wire ropes are often coated with corrosion-resistant materials to extend their lifespan.

Safety Innovations in Elevator Rigging

Safety has always been a top priority in elevator design and operation. Over the years, numerous innovations have been introduced to enhance the safety of elevator rigging systems:

Automatic Brake Systems:

- In the event of a sudden loss of tension in the wire rope, automatic brake systems engage to prevent the elevator from free-falling. This crucial safety feature was inspired by Elisha Otis’s original invention.

Emergency Communication:

- Modern elevators are equipped with advanced communication systems that enable passengers to contact building personnel or emergency services in case of an unexpected situation.

Load and Speed Sensors:

- Elevator systems are equipped with sensors that monitor the load and speed, ensuring that the elevator operates within safe parameters. If an anomaly is detected, the system can automatically initiate safety protocols.

Conclusion

As we ride elevators daily, it’s easy to take for granted the complex engineering marvels that make vertical transportation possible. Rigging and wire rope, often hidden from plain view, are the unsung heroes ensuring the smooth and safe operation of elevators. From the early days of hemp ropes to the sophisticated steel wire ropes of today, the evolution of elevator technology has been marked by a relentless pursuit of safety and efficiency.

Next time you step into an elevator, take a moment to appreciate the precision and innovation that goes into the rigging and wire rope systems, allowing us to effortlessly move between the floors of towering buildings. These unsung heroes are a testament to human ingenuity, providing a reliable and safe means of vertical transportation that has revolutionized the way we live and work in the modern world.

——————————————————————————————————————————————

The Hercules Group of Companies encompasses a wide portfolio of products and services across 7 diverse companies.