Synthetic Round Slings Inspection Download Guide

Synthetic Round Slings Inspection Download Guide

Synthetic round slings are an integral part of heavy-lifting and rigging. Similarly, proper sling inspection is integral to ensure the job is done safely and properly.

Read on to find out how to inspect your round slings for use.

Look and Feel for Damage

Most damage to a round sling can be found simply by looking. However, internal damage can be present as well. Inspect for internal damage by feeling along the slings’ entire length.

Minor Damage Causes Major Incidents

Damage to a round sling may seem minor or small, yet this can drastically reduce its ability to lift or hold heavy loads. This increases its risk of breaking during use−which can result in large costs, damaged material and most importantly, injured people.

In reality, no damage to a round sling is minor−if damage is present, it should not be used.

What Should Operators Look and Feel for?

- Missing Identification tag;

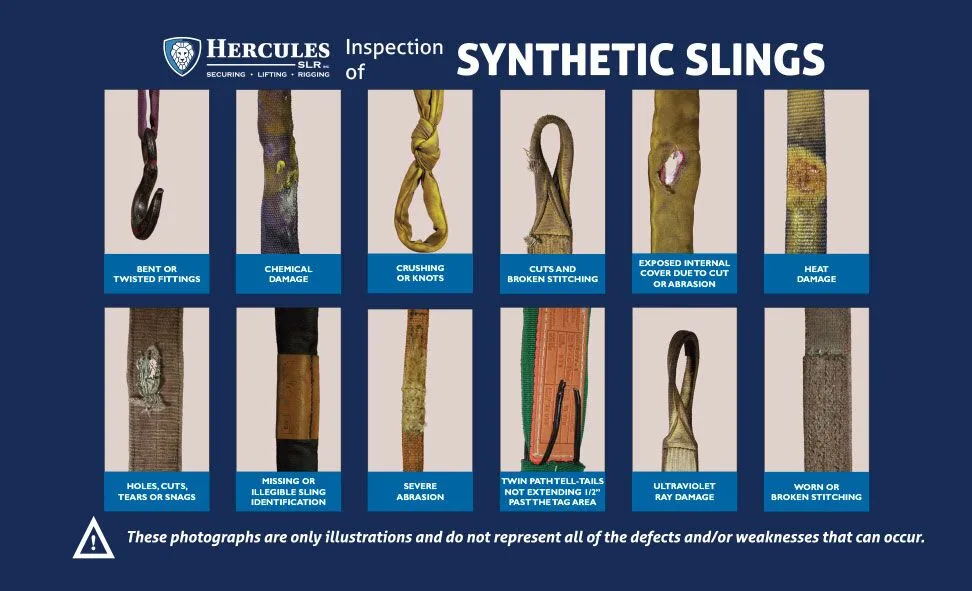

- Holes, cuts, tears, snags that expose core yarn, excessive abrasive wear;

- Broken or damaged yarn core;

- One or more knots are tied to round sling;

- Acid or caustic burns of round sling;

- Melting, charring or weld spatter of any part of round sling;

- Distortion, excessive pitting, corrosion or other damages to fitting(s);

- Broken or worn stitching in the cover which exposes the core yarn;

- Any conditions that cause you to doubt the round slings’ strength.

I’ve Found Damage−Now What?

If any damage is found, pictured above or otherwise, the sling must be removed from service. When removed, the sling must be completely destroyed, and must be made unusable for future use. If it’s repairable, it must be proof-tested by the round sling’s manufacturer or another qualified tester.

Sling damage should never be temporarily repaired.

Synthetic round slings are an integral part of heavy-lifting and rigging−however, proper inspection is also necessary to ensure the job is done safely, and properly. Keep reading to find out how often to assess your round slings before use.

Inspections—how often should I do this?

Round sling inspection should use the following 3-step procedure, which ensures slings are inspected frequently enough. The stages are:

Initial Inspection

When your sling is received, a designated employee will ensure the correct sling has been received, is undamaged and that it meets requirements for use.

Frequent Inspection

The round sling should be inspected before each shift, each day in normal service. When using for severe service application, the round sling should be checked before each individual use.

Periodic Inspection

Every sling should be periodically inspected by a designated person. However, this inspection should be performed by someone who does not regularly inspect the sling. This provides an opportunity to find issues that previous inspections may have missed or overlooked.

Period inspections are based on how frequently used slings are, or how frequently you anticipate you will use them for. Other factors include the severity of conditions and what type of work the sling is used for. Inspections may also be based on slings used in the past under similar circumstances.

Generally, inspections should be done as follows:

- Normal Service—yearly

- Severe Service—monthly to quarterly

- Special Service—as recommended by a qualified person

Intervals between inspection should never exceed one year. Written records are not required for frequent inspections, however written records should be kept. The WSTDA, RS-1 and ASME B30.9 require written record of the latest inspection.

——————————————————————————————————————————————

The Hercules Group of Companies encompasses a wide portfolio of products and services across 7 diverse companies