Innovations in Rigging Technology: What’s New?

Innovations in Rigging Technology: What’s New?

Rigging technology has come a long way since its humble beginnings, evolving from basic pulley systems to sophisticated engineering marvels that enable the construction of skyscrapers, the production of large-scale events, and the seamless operation of complex machinery. In recent years, the world of rigging has witnessed a surge of innovations that are revolutionizing industries across the board. This blog explores some of the groundbreaking advancements in rigging technology, showcasing how these innovations are reshaping the way we build, entertain, and operate machinery.

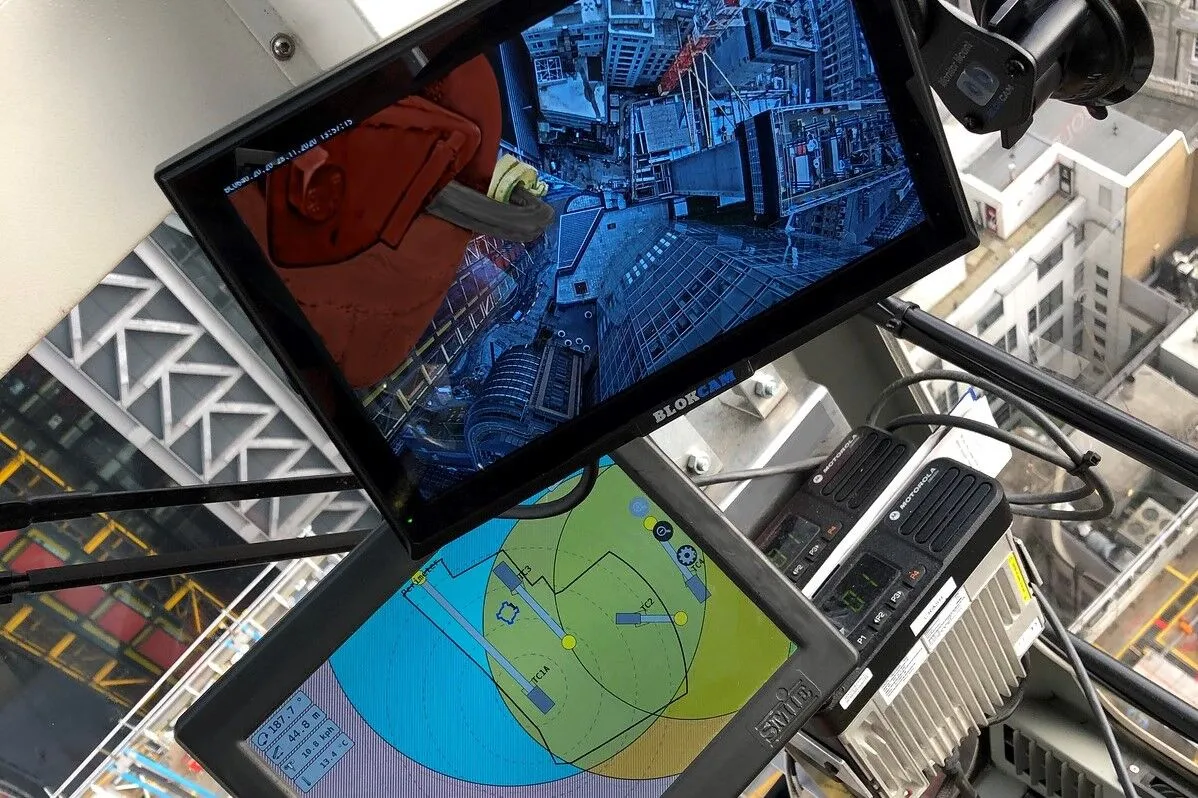

Crosby’s Blokcam system, available to order through Hercules SLR

Crosby’s Blokcam system, available to order through Hercules SLR

Wireless Control Systems

One of the most significant innovations in rigging technology is the development of wireless control systems. Traditionally, rigging operations required manual manipulation of ropes, cables, and pulleys. With wireless control systems, operators can now remotely control complex rigging setups with precision. These systems incorporate advanced sensors and intuitive interfaces, enabling real-time adjustments from a safe distance. This not only enhances safety by reducing the need for personnel to be near potential hazards but also streamlines operations and increases efficiency.

Automated Rigging Systems

Automation has permeated nearly every sector, and rigging is no exception. Automated rigging systems utilize robotics and computer-controlled mechanisms to perform tasks that were once labor-intensive and time-consuming. This innovation is transforming industries such as theater and event production, where stage setups can be rapidly adjusted with a few clicks, eliminating the need for manual labor. Automated systems also improve accuracy, reducing the risk of human error.

Load Monitoring and Predictive Maintenance

Safety is paramount in rigging operations, and innovations in load monitoring technology have made significant contributions in this area. Load sensors and monitoring devices are now integrated into rigging systems to provide real-time data on the forces being exerted. This information helps operators ensure that loads are within safe limits and prevents overloading, potentially preventing accidents. Additionally, predictive maintenance algorithms use data from these sensors to anticipate equipment wear and suggest maintenance schedules, minimizing downtime and reducing the risk of failures.

Smart Materials and Lightweight Design

Advancements in material science have led to the development of lightweight yet robust materials that are revolutionizing rigging technology. These materials enhance the portability and ease of setup for rigging equipment, making it more versatile and adaptable to various scenarios. Additionally, smart materials can offer built-in safety features, such as self-repairing capabilities or materials that change color when exposed to excessive stress, providing immediate visual feedback to operators.

Virtual Reality (VR) and Augmented Reality (AR) Integration

Virtual and augmented reality technologies are making their mark on rigging by offering immersive training and visualization tools. Training new rigging operators can be a complex and risky process, but with VR and AR, trainees can practice in a simulated environment that accurately replicates real-world scenarios. Furthermore, these technologies aid in pre-visualization, allowing engineers and operators to plan rigging setups and identify potential issues before physically executing them.

Energy-Efficient Solutions

The drive for sustainability has prompted innovations in energy-efficient rigging solutions. These advancements focus on minimizing energy consumption during lifting and lowering operations. Regenerative braking systems, for instance, capture and store energy that would otherwise be wasted, and then use it to assist in subsequent lifts. This not only reduces the overall energy footprint but also lowers operational costs.

The innovations in rigging technology discussed above represent just a fraction of the advancements that are reshaping industries worldwide. From wireless control systems to smart materials and VR integration, these innovations are improving safety, efficiency, and versatility in rigging operations. As technology continues to evolve, it’s exciting to imagine the future possibilities for rigging technology and the ways in which it will continue to transform the way we build, entertain, and operate machinery.

——————————————————————————————————————————————

The Hercules Group of Companies encompasses a wide portfolio of products and services across 7 diverse companies.