Load Distribution in Rigging: Unraveling the Science

Load Distribution in Rigging: Unraveling the Science

In the complex and high-stakes world of rigging operations, where precision and safety are non-negotiable, the science of load distribution stands as a fundamental pillar. Rigging professionals navigate intricate scenarios, manipulating heavy loads in diverse environments. Understanding the principles of load distribution is not just a theoretical exercise; it is a practical necessity that underpins safe and efficient rigging operations. In this blog, we will unravel the science of load distribution, exploring its principles and delving into why a profound comprehension of this science is crucial for the success of rigging endeavours.

The Foundation of Rigging: Load Distribution Principles

1. Grasping the Basics:

Load distribution, in the context of rigging, refers to the way in

which the weight of a load is spread or shared among the various

components of the rigging system. The objective is to ensure that the

load is evenly distributed to prevent overloading any single component

and to maintain stability during lifting and moving operations.

2. Center of Gravity: Understanding the center of gravity (COG) is paramount in load distribution. The center of gravity is the point at which the entire weight of an object can be considered to act, causing the object to respond to the force of gravity as if its mass were concentrated at that point. Rigging professionals must assess the load’s center of gravity to determine how it will behave during lifting and ensure that it remains within a stable position.

The Key Principles of Load Distribution:

1. Equalizing the Load: The principle of equalizing the load is fundamental in rigging. Rigging systems are designed to distribute the load among multiple points to prevent excessive stress on any single component. Whether using slings, chains, or cables, the goal is to ensure that each component bears a proportionate share of the load.

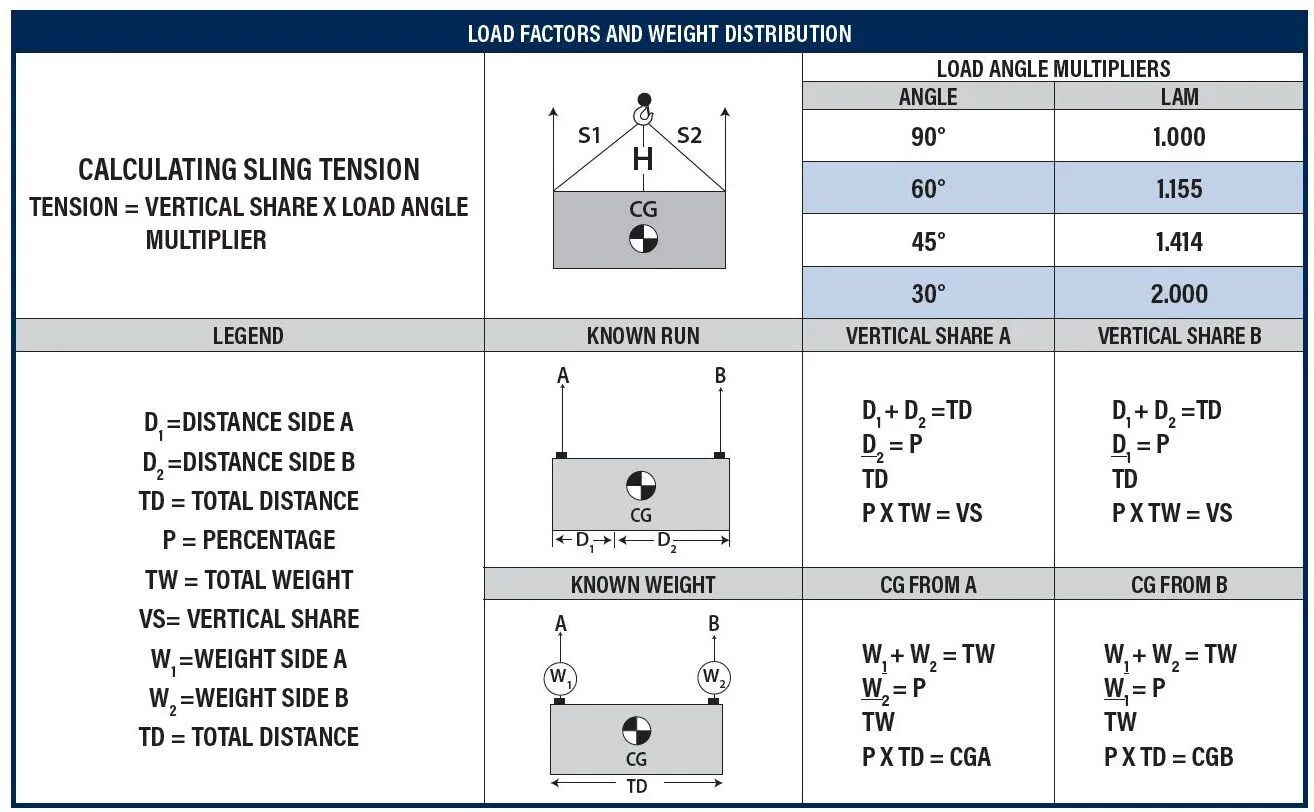

2. Angle of the Sling: The angle at which slings are rigged plays a critical role in load distribution. As the angle between slings decreases, the load on each sling increases. This is due to trigonometric principles, where the load’s weight is distributed across the horizontal and vertical components of the sling. Rigging professionals must consider the angle of the sling and adjust their calculations accordingly to maintain safe load distribution.

3. Equalizing Tension: In multi-point rigging systems, maintaining equal tension among all attachment points is crucial. Rigging components, such as spreader bars or lifting beams, are utilized to ensure that tension is distributed evenly across all points. This prevents uneven loading, reduces the risk of component failure, and enhances the overall stability of the rigging system.

4. Understanding Dynamic Loading: Dynamic loading occurs when forces are applied suddenly or change rapidly. Rigging professionals must account for dynamic loading, as it can significantly impact load distribution. Sudden starts, stops, or changes in direction can create additional stress on rigging components, necessitating careful consideration of the potential dynamic forces involved.

5. Rigging Configurations: Different rigging configurations, such as bridles and basket hitches, offer varying load distribution characteristics. Understanding the principles of each configuration is crucial for rigging professionals to choose the most appropriate setup for the specific load and lifting scenario. Factors such as load stability, balance, and weight distribution all come into play when selecting the optimal rigging configuration.

The Importance of Load Distribution in Rigging Operations:

1. Safety Considerations: Safety is paramount in rigging operations, and load distribution lies at the heart of ensuring a safe working environment. Uneven loading or overstressing of rigging components can lead to catastrophic failures, posing risks to personnel, equipment, and the surrounding environment. A thorough understanding of load distribution principles is essential for mitigating these risks and fostering a safety-first culture.

2. Equipment Longevity: Rigging equipment is a substantial investment, and proper load distribution practices contribute to the longevity of this equipment. By preventing overloading and distributing loads evenly, rigging professionals can extend the lifespan of slings, cables, hooks, and other components, reducing the frequency of replacements and maintenance.

3. Operational Efficiency: Efficiency in rigging operations is closely tied to load distribution. When loads are distributed optimally, the risk of delays due to equipment failures or adjustments is minimized. Rigging professionals can operate more efficiently, completing tasks with precision and confidence.

4. Compliance with Standards: Adherence to industry standards and regulations is a foundational aspect of rigging operations. Many standards explicitly address load distribution principles to ensure the safe and compliant execution of lifting operations. Rigging professionals must stay informed about these standards and apply load distribution principles accordingly to meet regulatory requirements.

Challenges and Considerations in Load Distribution:

1. Variable Load Characteristics: Rigging professionals often encounter loads with varying shapes, sizes, and characteristics. Each load presents unique challenges in terms of load distribution. Rigging experts must assess the specific attributes of each load to determine the most effective load distribution strategy.

2. Changing Environmental Conditions: Environmental factors, such as wind, weather conditions, or changes in terrain, can impact load distribution. Rigging professionals must continuously assess and adapt to these conditions to maintain safe load distribution throughout the lifting operation.

3. Communication and Coordination: Effective communication and coordination among rigging team members are essential for successful load distribution. Clear communication ensures that everyone is on the same page regarding the rigging plan, load characteristics, and any adjustments required during the lifting process.

Technological Advances in Load Distribution:

1. Load Monitoring Systems: Technological advancements have led to the development of load monitoring systems that provide real-time data on load distribution. These systems utilize sensors and telemetry to provide rigging professionals with insights into the forces acting on the load and the rigging components. This real-time feedback enhances the ability to make informed decisions and adjustments during lifting operations.

2. Simulation and Modeling Tools: Simulation and modeling tools allow rigging professionals to virtually assess load distribution scenarios before executing them in the field. These tools enable the visualization of load behavior, sling angles, and stress points, providing a valuable tool for planning and optimizing load distribution strategies.

In Conclusion:

Where the mastery of load distribution principles is integral to safety and success, education becomes a cornerstone for professionals striving for excellence. Hercules Training Academy stands as a beacon for rigging education, offering comprehensive courses that cover both the Fundamentals of Rigging and Advanced Rigger Technician levels. These courses not only delve into the theoretical aspects of load distribution but also provide hands-on practical experience, allowing participants to apply their knowledge in real-world scenarios. With a commitment to fostering a culture of safety, precision, and continuous improvement, Hercules Training Academy ensures that rigging professionals are equipped with the skills and expertise needed to navigate the intricacies of load distribution and elevate their performance in the dynamic field of rigging operations.

——————————————————————————————————————————————

The Hercules Group of Companies encompasses a wide portfolio of products and services across 7 diverse companies.