Eye Bolts: A Comprehensive Guide

Eye Bolts: A Comprehensive Guide

In the world of material handling, few tools match the fundamental versatility of the unassuming eye bolt. Despite their unassuming appearance, eye bolts play a crucial role in applications where loads need to be pulled away from or toward the eye. From construction sites to marine environments, these simple yet robust fasteners have earned their place in the toolkit of professionals and DIY enthusiasts alike.

But before you rush to purchase your next set of eye bolts, it’s essential to understand the ins and outs of these seemingly straightforward devices. From types and materials to sizing and installation, a well-rounded knowledge of eye bolts can save you time, money, and potentially prevent accidents. Let’s dive into the complete guide to eye bolts:

At their core, eye bolts are forged steel fasteners designed to create a secure lifting point.

Featuring a threaded shank with a ring or eye at one end, they can be affixed to structures such as wood, steel, or concrete. These bolts are commonly used with ropes, cables, or shackles to facilitate safe lifting operations.

Types of Eye Bolts

Eye bolts come in various sizes, materials, and finishes to suit different applications. Here are the five main types you should know about:

Regular Eye Bolt: Simple and non-shouldered, suitable for vertical lifts or overhead loads only.

Shoulder Eye Bolt: Also known as collared eye bolts, these feature a supportive shoulder or collar for added stability, enabling angular loading with proper installation.

Lag Eye Screw: Specifically designed for wood applications, these screws are screwed into thimbles without a designated working load limit.

Forged Eye Bolt: These bolts feature drop-forged eyes and are crafted from high tensile carbon steel, making them ideal for heavy-duty lifting tasks.

Stainless Steel Eye Bolts: With a high chromium content for corrosion resistance, stainless steel eye bolts are perfect for marine and architectural applications.

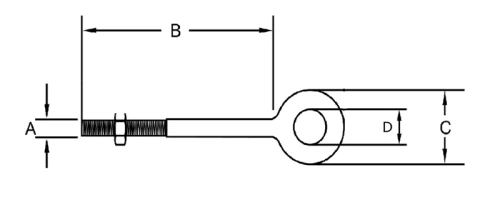

Understanding Eye Bolt Measurements

When selecting eye bolts, understanding their measurements is crucial. Key dimensions include:

(A) Shank Diameter (Thread)

(B) Length of Shank

(C) Exterior Eye Diameter

(D) Interior Eye Diameter

(E) Overall Length

The diameter and length of the shank are particularly important as they affect the working load limit and the thickness of the material the eye bolt will penetrate.

Calculating Eye Bolt Capacity

Eye bolts are rated based on their working load limit, which refers to the maximum load they can lift when loaded vertically through the shank.

However, the sling angle significantly affects this capacity:

- 5 degrees: 100% of working load limit

- 15 degrees: 80% of working load limit

- 30 degrees: 65% of working load limit

- 45 degrees: 30% of working load limit

- 46+ degrees: Not recommended

Understanding these angles is crucial for safe lifting operations.

Installation Tips for Eye Bolts

- Proper installation is key to the performance and safety of eye bolts. Here are some essential tips:

- Ensure the eye bolt is of sufficient length to penetrate the material.

- Tighten the nut securely to seat the eye bolt firmly and ensure the shoulder is flush against the surface.

- Use steel washers to fill any gaps, ensuring the thickness does not exceed one thread pitch.

Conclusion

From construction projects to marine applications, eye bolts are indispensable tools for lifting and securing loads. By understanding their types, measurements, capacities, and installation techniques, you can make informed decisions and ensure safe operations.

——————————————————————————————————————————————

The Hercules Group of Companies encompasses a wide portfolio of products and services across 7 diverse companies.