Ask the Experts | Everything Synthetic Web Slings

Ask the Experts | Everything Synthetic Web Slings

If you’re a rigger or work in material handling, you likely encounter synthetic web slings (or webbing slings) often in your work. A synthetic web sling is fantastic to lift delicate or soft materials, since their soft surface offers more protection than abrasive materials, like wire rope.

How many types of synthetic web slings are there?

Synthetic web slings come in two types — duplex and simplex. A duplex web sling is made with two synthetic fabric layers stitched together for extra reinforcement. A simplex webbing sling is made with only one synthetic fabric layer. “Just one layer? That won’t do anything,” you might be thinking—but how wrong you’d be! Even though a web sling may not have the same reputation for strength as say, steel, a web sling is surprisingly strong!

Web Slings in Action – Types of Web Sling Assemblies

- Single leg Web Sling – A single web sling has a master link, one webbing leg with a hook for lifting.

- Two leg Web Sling – A two-legged web sling has a master hook, two webbing legs, each with a hook on.

- Three leg Web Sling – A two-legged web sling has a master hook, three webbing legs, each with a hook on.

- Four leg Web Sling – A two-legged web sling has a master hook, four webbing legs, each with a hook on.

Extreme caution should be exercised in processes where lifts and slings are employed to move materials from one place to another. Operator training is essential and regular sling inspection should be conducted in order to avert accidents. Legislation has specific standards for lifting slings and prescribes various inspection criteria depending on the material used and the type of sling. Find out what is current in your area, be familiar with them and use them at all times.

Web Sling Certification Standards ASME B30.9-5

Generally speaking, any form of damage to a sling means that it should no longer be used. Regulations require that all slings should be permanently marked with their load capacity and employees may not exceed the load capacity of a sling. Lifting slings must be inspected before use on a daily basis.

Inspection Standards

- Government Appointed

- Standard ASME B30.9-5

- 9-5.9.4 Periodic Inspections performed by Hercules Qualified Inspector. Certificate issued upon passed Inspection, may include Proof Testing. Periodic Inspection shall not exceed 1 year.

- 9-5.9.3 Frequent Inspection

- Performed by Employee each shift, before the sling is used

What kind of damage makes a synthetic web-sling unusable?

- Increased stiffness of sling material.

- Acid or caustic burns.

- Melted, burned or weld spatter damage.

- Holes, tears, cuts, snags.

- Broken or worn stitching.

- Excessive abrasive wear.

- Knots in any part of the sling.

- Crushed webbing or embedded particles.

- Bleached sling color.

- Defective fittings (twisted, corroded, cracked, etc.)

- Exposure to extreme temperatures (lower than -40°C or higher than 90°C)

Hercules SLR offers inspections for securing, rigging, and lifting equipment. We inspect both large and small industrial rigging, lifting, material handling, and fall protection equipment—Our experts can provide service on-site, or at one of our 30 facilities found across Canada.

Frequently Asked Questions about web slings:

Q: What are web slings usually made from?

Answer: A flat webbing sling is usually made from woven polyester, nylon (otherwise known as polyamide) and polypropylene.

Q: Do flat web slings come in just one width?

Answer: Flat webbing slings come in different widths – but their ultimate flexibility and strength is noted by the number of webbing layers stitched together.

Q: Should I use paint or dye to color code web slings? This should help me identify them quickly and easily, right?

Answer: NO! Don’t use paint to color code webbing slings—the solvents in the paint could corrode the synthetic material. A torn or broken sling is unsafe, and will drastically reduce its SWL. To identify a synthetic sling’s material, look for the label color:

Polyester (PES)—Blue Label, or blue with a green line down the center of the webbing.

Polyamide (PA)—Green label

Polypropylene (PP)—Brown label

Q: What chemicals will affect webbing slings?

Answer: Polyester isn’t affected much by acid, but alkali’s will damage a polyester webbing sling. An alkali or alkaline is basically a substance with a pH level higher than 7. Examples of alkali substances are seawater, baking soda, bleaches, lye, and even blood. Polyamides are basically immune to alkali damage but are damaged by even moderately-strength acids. They can also lose up to 15% of their SWL when wet. Polypropylene is resistant to acids and alkali’s, which makes them a good choice when you have to lift something which needs protection from chemicals. Be sure the polypropylene is stabilized to protect from ultraviolet degrading.

Q: What markings should I look for on a webbing sling?

Answer: Look for the safe working load (SWL), identification number, and the label’s color code.

Q: How do I store my webbing sling?

Answer: It definitely matters! Be sure to store your slings in a dry, cool place. Keep them out of sunlight or other ultraviolet radiation, and don’t store them in damp conditions.

Q: So, they’re really strong – does that mean I can use them to lift anything?

Answer: Don’t use a webbing sling for a critical lift! Make sure you use extra caution and have a detailed lifting plan for using a webbing sling with delicate or fragile lifting operations.

Q: Okay, so what’s a critical lift?!

Answer: A critical lift is defined by WorkSafe BC as a lift with high-risk factors that could cause the crane or hoist to fail, or poses significant potential harm to human life. A critical lift is also one that needs a detailed rigging plan before the operation.

Other factors that can make a lift critical are:

- When a piece of powered lifting equipment exceeds it’s rated capacity by 75%;

- A mobile crane or boom truck goes over rated capacity by 90% lifting a load over 50% of its maximum permitted load radius;

- Tandem lifts— which is when more than one piece of powered lifting equipment is used or is used to lift another piece of lifting equipment);

- A person is being lifted;

- The load is under-water or submerged.

Q: Can I tie a knot in a webbing sling to make it shorter?

Answer: Never! Don’t knot, tie, or twist a webbing sling. Don’t manipulate the sling’s angle, either—use the sling however the angle forms naturally.

Q: When should I not use a webbing sling?

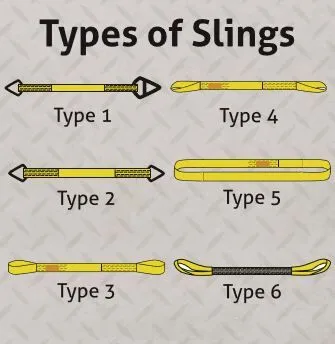

Answer: Don’t use a webbing sling if you don’t know the SWL. Don’t use if the eyes or other part of the webbing sling is damaged, if the sling’s eye opens more than 20°. There are 5 different types of possible webbing sling eye formations—see figure 1. If using a Type 1 webbing sling (called a choker sling), be sure to protect the eye before use.

Q: What should I keep in mind when using a webbing sling?

Answer: There are a few things to consider to use a webbing sling safely—you should always:

- Avoid shock-loading;

- Protect the sling with sleeves when sharp edges could tear its fabric—friction can cause heat damage, which is the most common form of ‘heat’ damage to webbing slings. To prevent, don’t let the sling run along the load’s surface and that it’s not pulled on any sharp corners. This is also known as ‘point loading’, when the load is pulled on a sharp corner, creating heat which results in heat fusion in the sling material.

- Never pull a sling from underneath a load.

——————————————————————————————————————————————

The Hercules Group of Companies encompasses a wide portfolio of products and services across 7 diverse companies.