Crane Pre-Use Inspection Checklist | What to Look For

Crane Pre-Operation Inspection Checklist

When it comes to crane inspections, keeping up with them on the required inspection schedule should ALWAYS be the #1 priority.

According to the Canadian Standards Association, crane inspections should follow standards outlined by ISO (the International Organization for Standardization)—Specifically ISO 4309 and ISO 9927-1.

However, in-between those required inspections, it’s always a good idea to be proactive about your workplace safety and perform pre-operation inspections.

If your company provides it, always use and follow maintenance checklists that include critical safety components as specified by the manufacturer, professional engineer and/or your company’s requirements. The following list is based on information provided by the Canadian Centre of Occupational Health and Safety (CCOHS) and can serve as a good starting point in the creation of a company-specific checklist that suits your crane and any specialized hardware being used more effectively.

Crane Pre-Use Inspection Checklist: What to Check for During Pre-Operation Inspection

All capacity markings are present

- All rope has no sign of kinks, cuts, breaks, corrosion, reduced diameter, broken strands of wires or other signs of wear or damage.

- Rope drum cable is positioned correctly in the groove tracking and the means of anchoring is correct with no wear or damage.

- Sheave ropes and guides are aligned correctly, and there’s no wear on the sheave groove.

- All hooks are free of cracks, deformation, bent safety latches, broken springs or other signs of wear or damage.

- You’re using the appropriate type of sling with legible and appropriate capacity ratings, with no holes, cuts, crushed wedding or other signs of damage.

- All lights are working properly with none burnt out or broken.

- Mechanical parts and guards aren’t loose, bent broken or missing.

- Rails aren’t broken chipped or cracked.

- No signs of wear on wheels (shown by bumpy riding).

- Bearings aren’t loose or worn.

- No signs of shoe wear on brakes.

- Bridge bumpers and trolley end stops aren’t loose, missing or improperly placed.

- Controller and collector shoes or bars aren’t worn, pitted, loose broken or in faulty operation.

- All control buttons are labeled to indicate their function, are properly functioning and release immediately without sticking.

- All boards, railings, and ladders in the foot walk zone are in appropriate condition.

- All gears are properly lubricated with no presence of foreign materials in the gear teeth (indicated by grinding or squealing).

- A fire extinguisher is present in the crane cab.

- Before closing the main or emergency switch, ensure no one is on or around the crane – even when starting on regular duty.

- Before closing the main switch, make sure that all controllers are in the “off” position.

- Inspect oil after opening and locking out the main switch.

- Make sure no overhead power lines are obstructing the crane operation.

Document these findings clearly in your maintenance logbook which should include all tests, repairs, modification, and maintenance. Keep this logbook with the crane and call upon certified professional inspection technicians and engineers as required. Never operate the crane if based on these findings it does not seem to be in safe working condition.

Crane Pre-Use Inspection Checklist: What to Inspect While the Crane is Moving

Before lifting any load with a crane, you should always inspect it while it is moving. During this inspection you should be looking out for:

- Smooth play out of wire rope to and from a drum.

- Sheaves are turning without binding or jerking as a rope passes over them.

- Ropes are properly aligned where it enters the sheaves.

- Ropes aren’t rubbing on the rope sheave guards.

- No rubbing, scraping, or clattering noises during operation.

- No jerky movements.

- Controls and brakes are operating properly.

You should also test that the limit switch is working properly by slowly raising the hook block with no load attached to the hook.

When it doubt, always call upon the experts.

These pre-operation inspections should only be used as a way to stay on top of typical wear and tear that may lead to required maintenance.

Without inspections and maintenance, equipment failures can have a major effect on business costs, cause unscheduled outages and most importantly, could cause major and possibly deadly safety hazards. Hercules SLR offers crane certifications & LEEA-certified inspections, repairs, predictive & preventive maintenance (so you can pass those inspections!) and crane parts & accessories like wire rope slings, hoists & whatever else you need to lift.

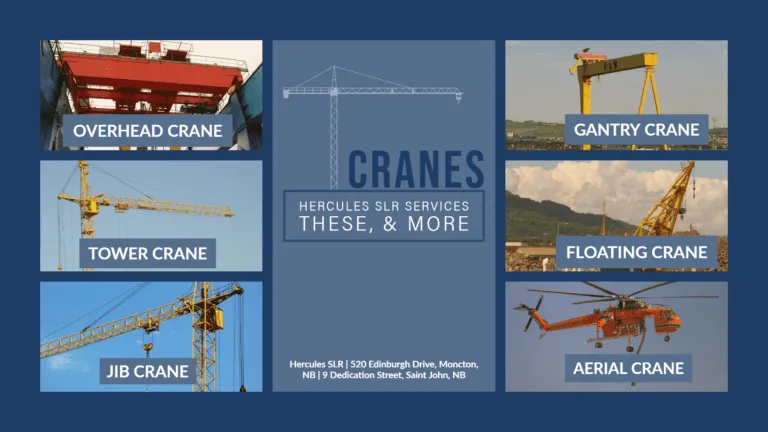

Hercules SLR has qualified technicians to inspect and service all crane classes, specifically:

- Overhead/Bridge Cranes

- Top Running Overhead Crane

- Under Running Overhead Crane

- Modular Crane

- Gantry Cranes

- Tower Cranes

- Rail Road Cranes

- Floating Cranes

- Aerial Cranes

- Jib Crane

Have a type of crane you need serviced, but we didn’t cover it here? Give us a call—We service anything.

Find it difficult to track when your crane is do for a full inspection? We know, and we listened. Receive crane service from Hercules SLR and gain access to our free asset management service, CertTracker!

——————————————————————————————————————————————

The Hercules Group of Companies encompasses a wide portfolio of products and services across 7 diverse companies.