Beam Clamp Applications: safety tips from Brampton, ON

Beam Clamp Applications: safety tips from Brampton, ON

Beam clamp applications provide support and better load control. Today, we spoke with rigging experts from Brampton, Ontario to learn more about the three main types of beam clamps—they spoke with us about safe tips for use and how to inspect your beam clamp before application.

Beam clamps: 3 different types

There are three different types of beam clamps:

- Scissor type

- Adjustable type with fixed jaw

- Adjustable type with swivel jaw

1. Beam clamps: scissor type

While not the most popular type of clamp, the scissor beam clamp is still one of the basic types of clamp, and is ideal for lifting applications. It uses scissor action to manipulate the weight of the load to apply clamping load. It’s clamping jaws are rougher, which helps to dig into the load and form a better grip.

Before use, be sure to check its condition—assess the pivot bolt, wear and deformation and check the SWL, identification and use of beam to be used on.

2. Beam Clamps: adjustable type (fixed jaw)

Before use, check the tommy bar, screw thread and screw spigot for wear and deformation. Check SWL and identification, and also check for general condition.

3. Beam Clamps: adjustable type (swivel jaw)

Before use, be sure to check the swivel jaws and ensure they move freely, check the SWL and identification and the tommy bar, screw thread and screw spigot for wear and deformation.

Beam clamp applications: inspect before use!

Before using your beam clamps, be sure to follow these pre-use inspection tips:

Check SWL, Identification no. and colour code

Check SWL of the clamp’s within the weight of the load to lift;

Check the clamp is the correct size for the beam;

Thoroughly examine the clamp for wear, damage and deterioration—particularly at the hinge and shackle attachment points;

Ensure the screw thread is in good condition—this means it’s not bent and rotates freely;

Check the tommy handle for damage and distortion;

Check jaws for damage, distortion and ensure the swivel type is free to rotate;

Ensure screwed spigots aren’t damaged, distorted or worn excessively.

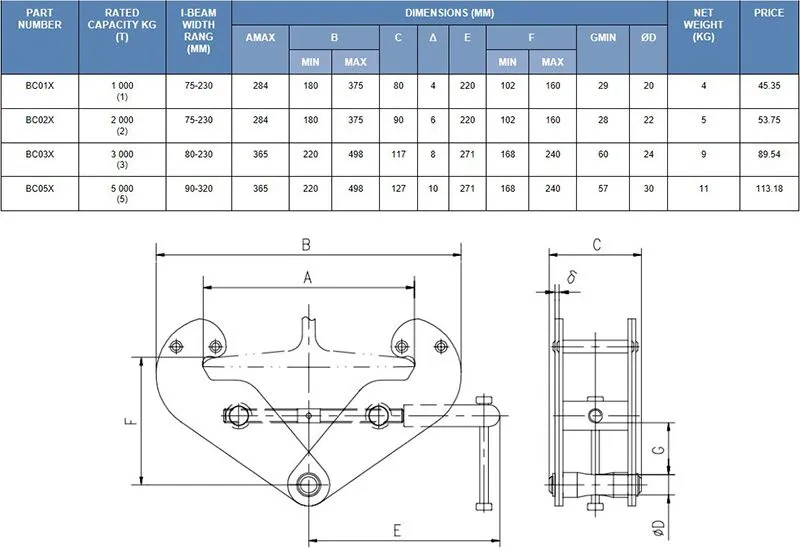

Hercules Bronze and Blue Beam Clamp (Above)

Beam clamp applications: more tips for safe usage

- Don’t exceed the SWL of beam clamp;

- Don’t exceed SWL of beam that the clamp’s secured to;

- Make sure the beam clamp is correctly and securely clamped to the beam and the centre line of the clamp suspension point is in alignment with the centre line of beam;

- Contact the beam clamp supplier before replacing bolts—this could lead to the wrong screw being fitted and may cause damage to the beam clamp;

- Ensure you’re using a certified beam clamp;

- Ensure a competent person is applying the beam clamp—a “competent worker or person” is defined differently in each province according to OH&S rules. British Columbia and Quebec are the only two provinces which don’t formally define what a “competent worker/person” is. Click here for the Canadian Centre for Occupational Health & Safety’s definitions of “competent” in each province or territory.

- If using two clamps in tandem, you may need to use ancillary equipment, like a spreader bar;

- Use beam clamps for vertical lifts only. (See ‘side loading’ below).

Beam clamp applications: side loading

Standard beam clamps are designed for in-line use only. If the ID plate says to use the clamp at 0° only, do not use side-loading—use the angle that’s permitted. Beam clamps that are suitable for side loading are fairly new to the lifting industry—the IPU10 and IPU10S by Crosby, for example are meant to lift in any direction. View the Crosby IPU10 flyer and its specs here.

Universal beam clamps can be used as an anchor point to lift and pull, load at any angle up to 90° without lateral and longitudinal de-rating and for low headroom use.

Is your hardware up-to-date? We inspect, repair & certify rigging equipment:

Have your beam clamps been inspected lately?

Don’t worry about tracking equipment inspections—our asset management tool, CertTracker™ is a virtual lifeline to safety—and the best part? It’s free for all customers when your inspection is done by Hercules SLR.

CertTracker™ reminds you of inspection dates and timelines, helps you stay compliant with provincial and national safety standards and overall, reduces the ownership cost of your equipment.

Browse Bronze & Blue here or e-mail us at [email protected] to rent a beam clamp for your next project.

——————————————————————————————————————————————

The Hercules Group of Companies encompasses a wide portfolio of products and services across 7 diverse companies.