Poly-What?! All About Synthetic Slings

Synthetic slings are generally available in two varieties – flat-woven web slings and round slings. Textile slings should perform in accordance with ASME standards B30.9-5.

Synthetic Slings: flat-woven web sling (or webbing sling)

Synthetic flat-woven web slings are usually made with woven polyester, polyamide (which is a fancy word for nylon) or polypropylene, and have an eye (basically, a loop) stitched at each end. They are available in Simplex (one layer) or Duplex (two layers).

Web slings are made with a safety factor of at least 5:1 – although other industries may require a higher safety factor.

Synthetic Slings: round slings

Round slings (also known as ’roundslings’) are made from load-bearing fibres with a protective, abrasion-resistant outer later. Their round form is known as ‘endless construction’, and are available in different lengths and capacities.

Synthetic Slings: beat the heat

Consider the temperature of both your surroundings and the load you will lift – synthetic materials have selective resistance to heat, which will effect which sling you choose.

Synthetic sling heat ranges are:

- Polyester and polyamide: -40°C to 100°C

- Polypropylene: -40°C to 80°C

These synthetic materials protect against a variety of chemicals, however – they offer different levels of protection against chemicals like acids. Synthetic sling chemical resistance is:

- Polyamide (Nylon): Resistant to the effects of alkalis, but is attacked by acids.

- Polyester: Resistant to acids, but damaged by alkalis.

- Polypropylene: Shows little affect from acids or alkalis. Sustains damage from solvents and paint.

Synthetic Slings: colour codes

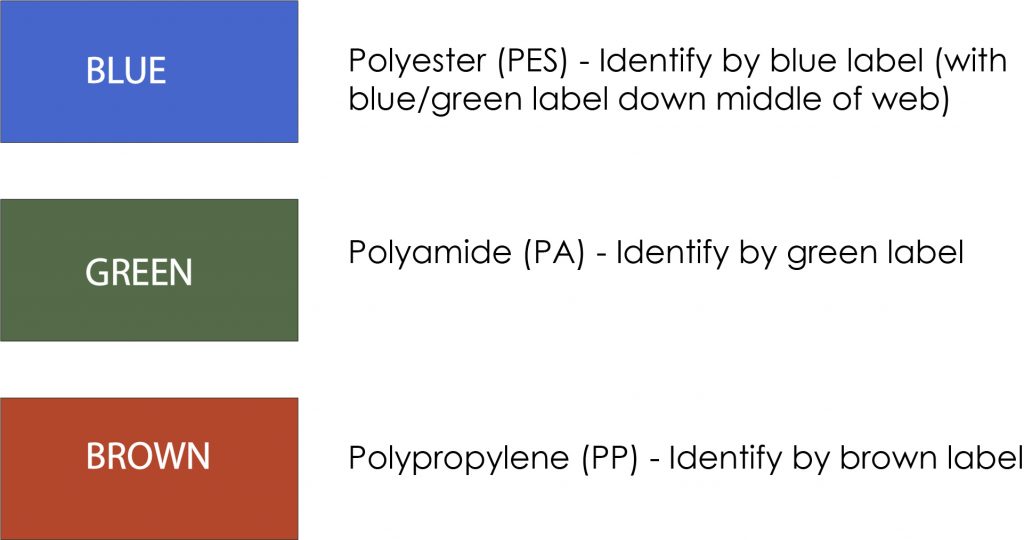

Synthetic material in slings are colour coded, in order to identify them properly. The label will be a specific colour, and may also have the type of material written as an abbreviation.

The colour codes are:

Synthetic Slings: eye formations

Synthetic Slings: eye formations

The loop at the end of the web sling is called an eye formation – there are various formations to suit different applications.

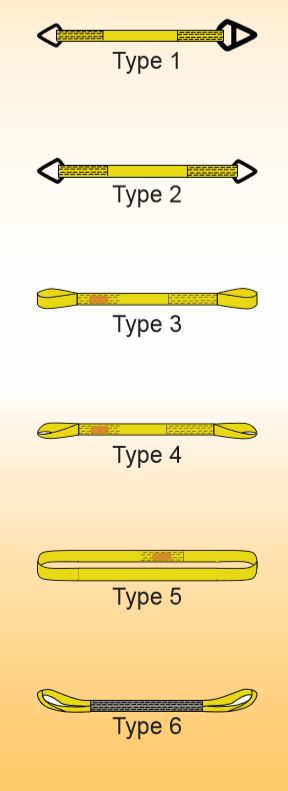

There are six different types of web sling types – see figure 2. The six names for these slings are:

Type 1—Choker

Type 2—Basket

Type 3—Eye & Eye

Type 4—Twisted Eye

Type 5—Endless

Type 6—Reversed Eye

Synthetic Sling: round slings

These are made with multiple, high-tenacity yarns, which are covered with a protective sleeve. These are usually made from polyester – but, polyamide (nylon) and polypropylene are available too.

To identify these slings, an identification label is sewn into the cover which details user information and traceability requirements.

They are flexible, light-weight and very flexible.

Synthetic Sling: pre-use inspection

Follow these steps before using your synthetic sling each time – this will ensure you and coworkers will stay safe, and eliminates potential of the sling breaking and damaging the load.

If you find damage on your synthetic sling, it should be removed from service immediately – refer it to a competent person to have it inspected and repaired if necessary.

- During your pre-use check, you should:

- Check the sling label is present and legible and includes manufacturer, rated load for at least one hitch, material type, number of legs (if more than one) and the manufacturers code/stock number.

- Check that the sling body has no signs of tears, cuts or severe abrasion

- Check formed eyes for damaged stitching

- Verify end fittings (where present) function correctly and are undamaged.

- Check for signs of chemical damage.

- Check that sling has undergone its periodic thorough inspection.

- No knots in sling.

Synthetic Slings: shackles, hooks n’ hardware

When you attach a sling to hooks or shackles, take care to ensure the slings don’t bunch around the accessory. Bunching can cause damage since only a portion of the webbing supports the load.

When securing a load with webbing slings, don’t be concerned with the d/d ratio (diameter around the bent sling divided by the body diameter of the sling) – but you must consider the width of the webbing. Follow the manufacturer’s recommendations when you lift with synthetic web slings.

Note: the sling that lies in the shackle fits perfectly – there’s no bunching or a sling that protrudes from the shackle pin.

Hercules SLR – Custom Rigging and Lifting Solutions

Hercules SLR offers custom lifting solutions. We’ll match you with the best equipment and hardware for your project needs, and we’ll customize equipment to meet your specifications.

Need a lift? Drop us a line at [email protected] to speak with one of our rigging experts – we’ll take you where you need to be.

Need proof? Read about the Frankensling we made for The Town of Oakville Marina, our rigging fundamentals course that Hercules staff from across Canada completed at the Hercules Training Academy, keep your synthetic round slings in good working order with our Free Downloadable Synthetic Round Sling Inspection Guide or read our blog on how to prevent synthetic round sling damage.

——————————————————————————————————————————————

The Hercules Group of Companies encompasses a wide portfolio of products and services across 7 diverse companies.